Our laboratory has continuously improved and expanded over our 40 years of business and we now have extensive testing facilities available on site.

Lab Facilities

We have established a good relationship with our numerous test equipment suppliers, and we plan to continue to expand our testing capabilities in the future. We hope to introduce additional test equipment that will further improve our ability to evaluate the performance and processing characteristics of our compounds, as well as supporting our customers in the test results that they require.

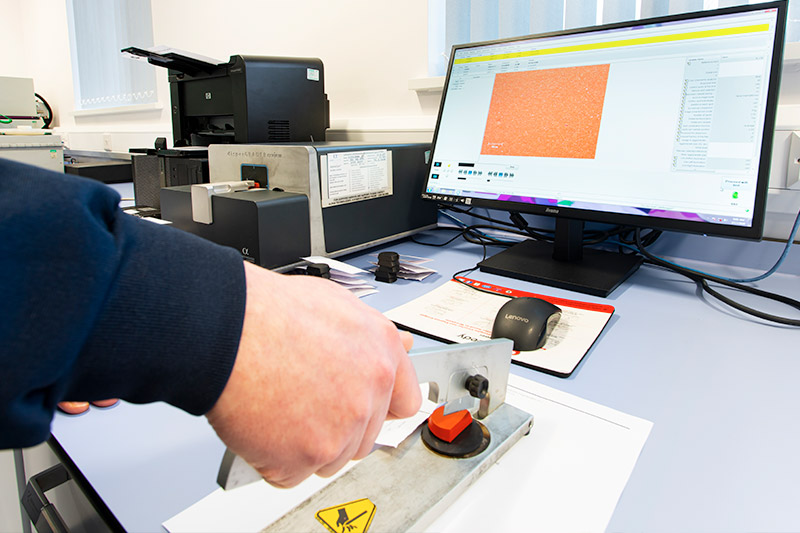

Quality control is always our number one priority and our approach is to assess the compounds as they are being mixed and feedback any relevant information to our processing operators in real time. This allows us to identify any batches that deviate from the mean and investigate the cause so that we can take relevant preventative measures to ensure the batches sent to dispatch are of the highest quality and meet our internal QC limits. Testing gates and limits are continuously maintained by a dedicated process controller we have operating on site.

Moving die rheometers (MDRs), Mooney viscometers, Dispergraders and Colour Spectrophotometers are among the test equipment utilised at this stage.

Provided they meet our stringent quality control requirements, batches that require additional testing are then sent to our specification testing area. We regularly test compounds to AMS, DTD, MIL, BS, ASTM D2000 and Def Stan specifications. If you require testing to industry specific specifications or prefer to use your own internal specifications, we can add them to our system.

The test equipment used in this area includes: Tensometers, Compression set jigs, Ozone cabinet, Gehman torsional stiffness (Low Temperature), Non-brittle (Low Temperature) and ovens for accelerated ageing and fluid immersion tests.

Standards We Work To

| Hardness | BS ISO 48 | ASTM D2240 | ASTM D1415 |

| Dispersion | BS ISO 11345 | ASTM D7723 | |

| Density | BS ISO 2781 A1 | ASTM D297 pt16 | |

| Tensile | BS ISO 37 | ASTM D412 | |

| Tear Strength | BS ISO 34-1 | ASTM D624 | |

| Compression Set | BS ISO 815-1 | ASTM D395 | |

| Heat Resistance | BS ISO 188 | ASTM D573 | |

| Effect of Liquids | BS ISO 1817 | ASTM D471 | |

| Ozone Resistance | BS ISO 1431-1 | ASTM D1149 | |

| Low Temperature | BS ISO 1432 | BS ISO 812 | ASTM D2137 |

| Corrosion Resistance | BS ISO 6505 |

Supplying High Quality Elastomeric

Compounds and Technical Expertise

to meet rigorous customer requirements

and new industry standards